Imagine. You’re the restaurant manager at Indiana’s top grossing Applebee’s restaurant. It’s your peak service time. You hear hustling, bustling and laughter. Indoor customers are enjoying their meals, planning their weekend activities, and keeping socially distant. Carryout, curbside pick-up, and delivery orders are flying out the door – left and right.

Then, BAM it hits! Your sanitary sewer line clogs and it’s backing up. Waste begins to overflow from the restaurant’s kitchen and restroom floor drains. You immediately close the restaurant and quickly clear out all customers and employees. Business operations come to a halt. You’re standing in the middle of a complete mess. Now what?

True story. It happened to Ryan Cain, the General Manager at the Applebee’s restaurant in Greenwood, Indiana in mid-November 2020. Discover how VASEY identified and solved the problem.

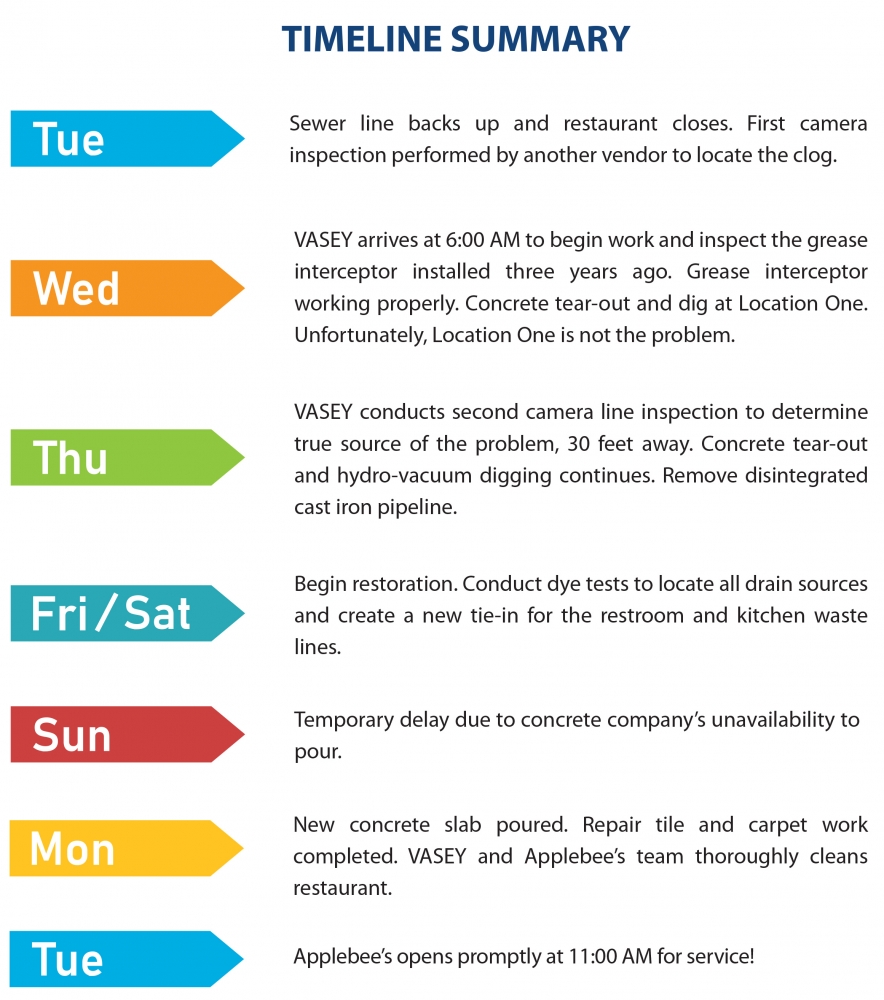

Cain, the restaurant’s manager, called a reputable, long-time vendor to conduct a pipe inspection. The location of the clog was identified; however, this vendor didn’t do dig work or handle repairs. Next, Cain called VASEY’s Plumbing Manager, Mike Bogan, and said, “If VASEY can get here tomorrow, you’ve got the job!”

The following morning at 6:00 AM, Bogan and the VASEY team were at Applebee’s. First, VASEY checked obvious problem sources, including a relatively new 1,000-gallon grease interceptor they installed three years prior. After inspection, they determined the interceptor was working properly and it wasn’t contributing to the existing sewer backup.

VASEY was hesitant to start repairs without doing their own camera line inspection. However, being in shut-down mode, and with Cain’s previous long-term vendor relationship (15 plus years), he resolutely insisted they immediately dig at the predetermined location.

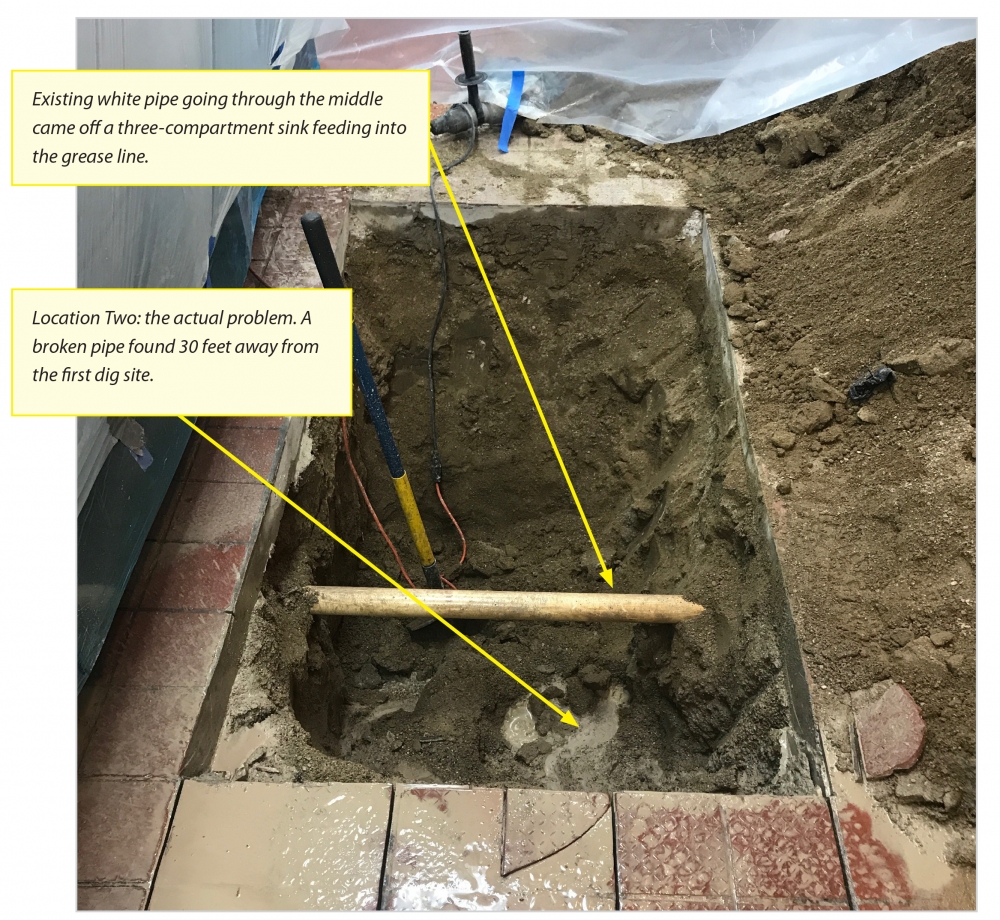

If the situation had only been that simple. The first location wasn’t the source of the problem. However, there was a silver-lining. Digging at the first location provided VASEY easier access to snake and perform a second camera line inspection to identify and locate the true problem – a break in the sanitary line located 30 feet away. Side note: a restaurant’s sewer problems are most often related to the sanitary line (restroom waste), or fat, oil, and grease build-up (kitchen waste).

During the restoration process, Bogan was in constant communication with Cain and the Applebee’s State and Regional Managers (overseeing 57 and 565 locations respectively). Prior to being a restaurant, this location was a bank. Assuming the plumbing fixtures were original, it was simply a matter of time before a sewer system failure occurred.

After four, 10-to-12 hour days of hydro-vacuuming, trenching, capping broken pipes, dye testing, installing, and tying in new drain lines, VASEY repairs and clean up were complete.

Tie in location for the bathrooms (to the left). VASEY inserted camera and drain-jetter to determine the true source of the problem.

Dig Location Two: On the cook’s line, about 30 feet away from Location One. On the right, sits the commercial stoves (where the sand and pea gravel are built up). On the left, the reach-ins, where all food is prepped. Due to the food prep line’s location, the existing pipe was capped and a new line added, tying back to the restrooms. VASEY thoroughly inspected the entire facility to identify the grease and sanitary lines and what pipes fed into each system.

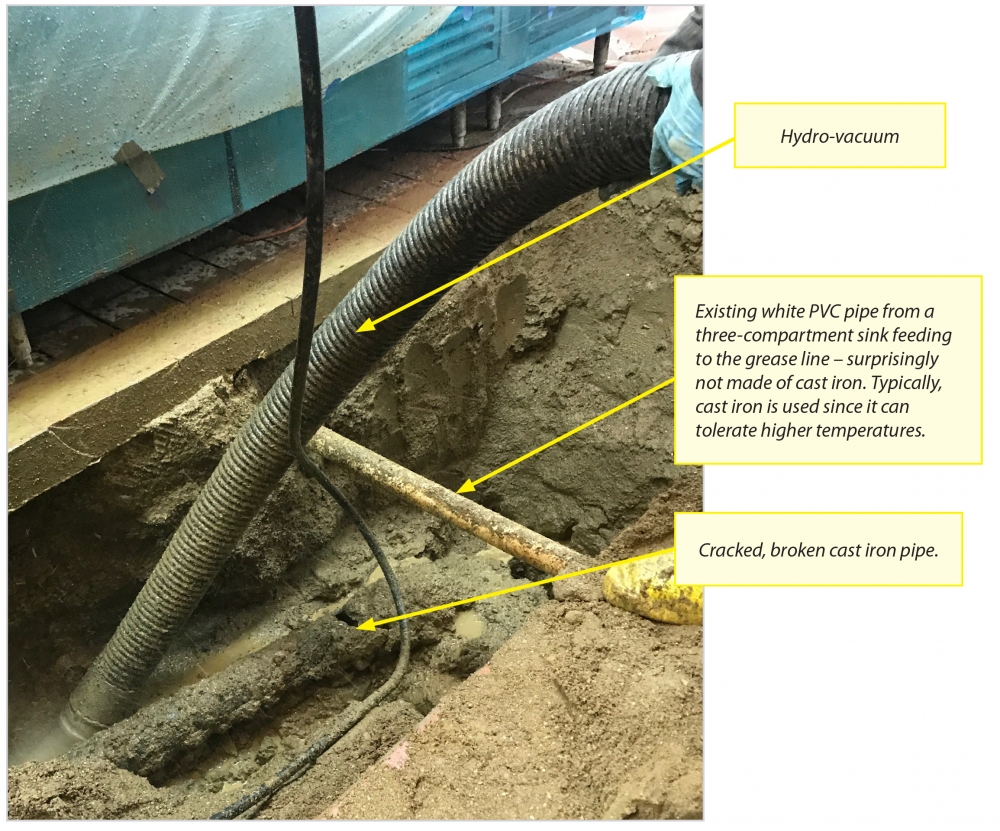

Dig Location Two: fully exposed, broken cast iron pipe. Once the damaged pipe was exposed, it disintegrated. Upon closer inspection, the entire pipe cracked along its bottom side (normally cast iron pipes fail “bottom up” because that’s where the grease settles. The average life span of a cast iron pipe ranges from 20 to 30 years).

Toward the upper right, a hydro-vacuum which used high pressure water to break up hardened clay and dirt. The dry soil is turned into a wet slurry to facilitate removal by suction.

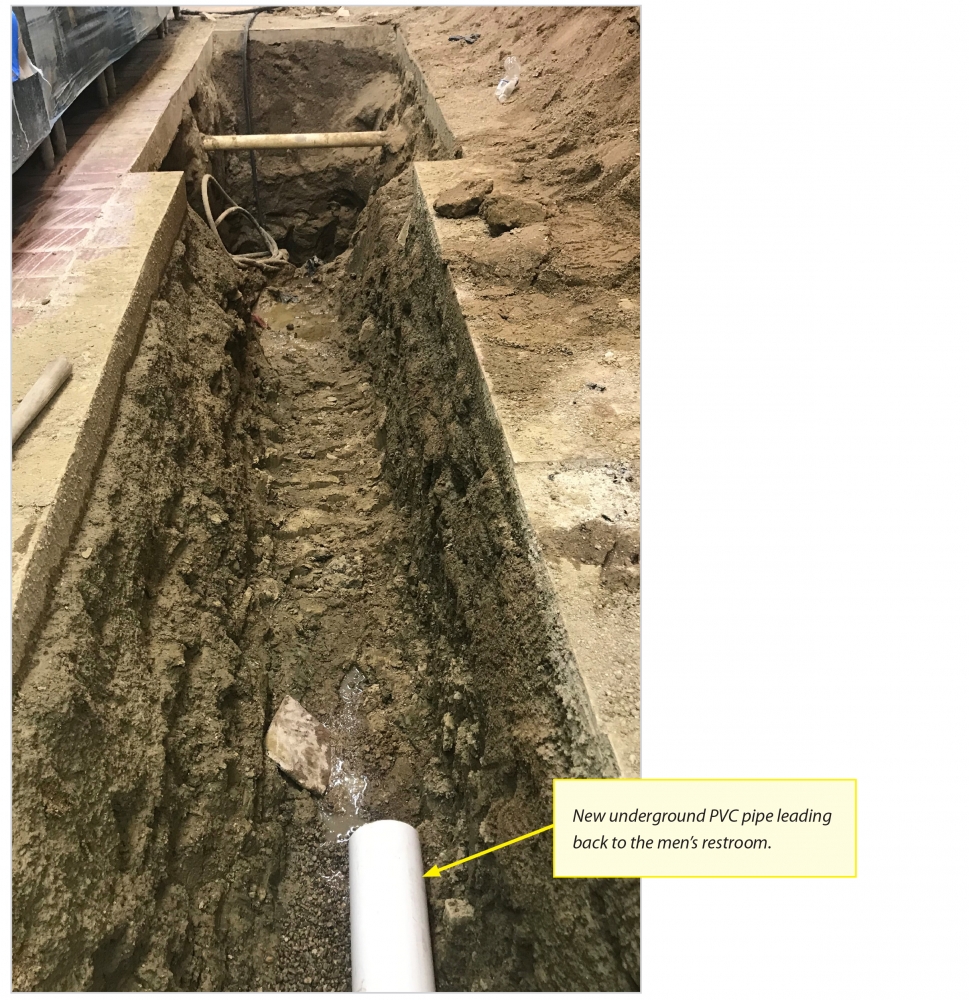

The power of Hydro-vacuuming: an 8-inch layer of sand and concrete-like dirt. The entire trench (4 feet wide x 10 feet long x 5 feet deep) was hydro-vacuumed quickly. Manually, with pickaxes and multiple men, it would have taken endless man-hours.

Dye testing utilizes dye tracer tablets that are safe, non-toxic and biodegradable. Similar to food coloring, a plumber places a red, blue, or yellow tablet in the sink; runs water over it and tracks where it comes out. It verifies everything from the point of origin is flowing properly into the grease interceptor or into the sanitary line.

PVC pipe shown is going underneath the wall into the men’s restroom. VASEY had to cut the floor and find a good place to tie in to allow the waste to drain from the bathroom to the white PVC pipe and out of the building.

VASEY cut the pipe in the fore front to verify the remaining floor drains throughout the facility and to make sure nothing was feeding back into the grease line. VASEY dye tested every drain and pipe in the facility, tracking its flow to make sure everything else was 100% correct.