How do you successfully and expertly wield your power over an airborne beast? Specifically, a 2,500-pound HVAC rooftop unit? At VASEY, we do it with careful planning, detailed procedures, safety, and flawless execution.

An American Retail Chain, Headquartered (HQ) in Indianapolis, has been a VASEY customer for more than 25 years. The Indianapolis corporate facility has a total of 120 HVAC units – 83 are rooftop units and the remaining are computer room units, air rotation units, ducted split systems, and ductless splits. The 600,000 sq. ft. facility includes both the office and warehouse spaces which are heated and/or cooled 24 hours per day – 7 days a week – 365 days per year.

Ironclad procedures are necessary to ensure safety. For this installation, VASEY needed a 5-man crew on the roof and another 5-man crew on the ground for each HVAC unit – 1 man on each corner and 1 spotter to communicate with the pilot.

First, the team loosens the old units from their curbs making them lift ready. After the clamp or shackles are attached to a unit, the four men located on the corners raise their hands and signal thumbs up; next, they step back away from the HVAC unit to denote “all clear.” The spotter whose sole responsibility is to communicate with the pilot advises when it’s safe to lift off the old HVAC unit. On the ground awaits another 5-man team to detach the old HVAC unit and then attach the new replacement unit.

The single man chopper holds approximately 250 gallons of fuel. With a military-grade chopper and rotor package, the chopper’s lift capacity is 6,500 pounds. (Upper left photo – cargo hook. Lower right photo – helicopter cockpit)

Given the amount of risk, this type of installation can only occur with careful preparation, diligence, and mindfulness. Rick Cope, Director of Project Sales and a 33-year VASEY veteran, served as the primary point person for the operation. Having proven logistic and safety procedure expertise for this type of operation is critical.

Steps included:

- Onsite safety training for all VASEY team members involved in the operation.

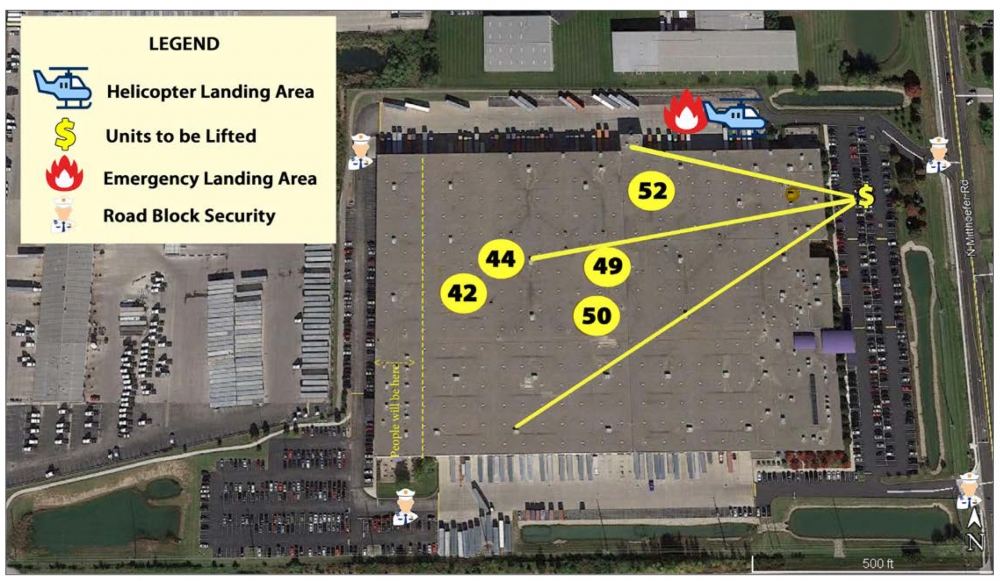

- Determining and mapping out the location of all power lines and light posts.

- Defining a landing pad and an emergency landing pad area for the helicopter.

- Creating detailed diagrams denoting the staging of both the old and new HVAC units.

- Coordinating a schedule and flight plan with the airport authorities.

- Working in tandem with HQ’s security team to block off and clear all vehicles and people

from the entrance, exit, flight path, and safety zones. - Accounting for all VASEY and HQ team members.

- HQ wanted to avoid 100% building evacuation and prevent a total work

stoppage. After conferring with the helicopter company, VASEY safely

accommodated their request. - VASEY measured the exact location of the five rooftop units to ensure every person

within the facility was at least 175 feet away from the nearest HVAC unit. HQ

employees on duty gathered in the break area during the lift. - While VASEY only partners with the most experienced, heavy-lifting helicopter

companies, the detailed preparation is necessary to prevent loss of life or property

in unforeseen circumstances.

- HQ wanted to avoid 100% building evacuation and prevent a total work

Before onsite training with the pilot (front left), VASEY double checked OSHA’s requirements – safety glasses were required to protect their eyes from flying debris; however, with the helicopter’s updraft, hard hats were optional.

Beginning early on a Saturday morning, the VASEY team disconnected all the power and gas lines and used a jack to lift the old HVAC units up slightly off the curb to loosen them, making it easier for the chopper to lift. With speed and efficiency, VASEY removed the five old 2,500 lb. units and replaced them with the five new 2,500 lb. units in less than 30 minutes. On Sunday (the next day), VASEY finished the installation and hook ups – power, controls, and system turn on. Limiting downtime was essential as HQ had cardboard packaging that was sensitive to humidity.

Standard procedure dictates once an installation is complete, the old HVAC units are loaded on trailers and taken back to VASEY’s facility. A reclamation specialist recycles the units’ old refrigerant to safely meet EPA standards. Sidebar: in the previous year, at HQ, VASEY changed out 11 perimeter units with two heavy-lift cranes in a single day.

(Left) C.F. – HQ Facilities Manager

(Right) Roger Mooney – VASEY Sales Manager

To effectively maintain commercial facilities, it takes an experienced company with an accomplished and qualified team. At VASEY, we invest in our customers’ well-being. We are dedicated to long-term relationships and we actively listen. More important, safety is always our first priority. VASEY brings an undeniable skill set and level of deliverables to the table.

With the investment required in a heavy-duty lifting HVAC project, VASEY operates with safety, speed, and efficiency to protect our customers’ employees, property, and bottom line.